Diamond polishing pads offer a quick and effective method of polishing granite, marble and other stone materials and are ideal for the professional stone mason, kitchen fitter and other sectors, such as monumental stonemasons.

The huge popularity of granite and marble as a surface in kitchens has meant that there has been a surge in demand in recent years for polishing products, which offer reliable results as efficiently as possible.

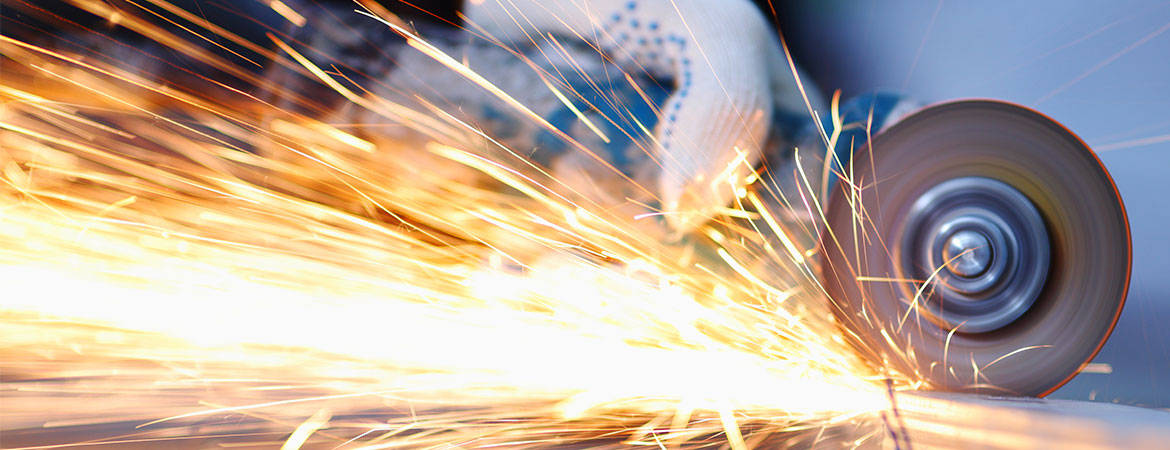

With the right tools, polishing granite, marble and even suitably cast concrete to achieve a high shine finish is relatively simple. The polishing process involves effectively grinding the stone using increasingly fine abrasives and for this a grinder and a set of diamond polishing pads is required.

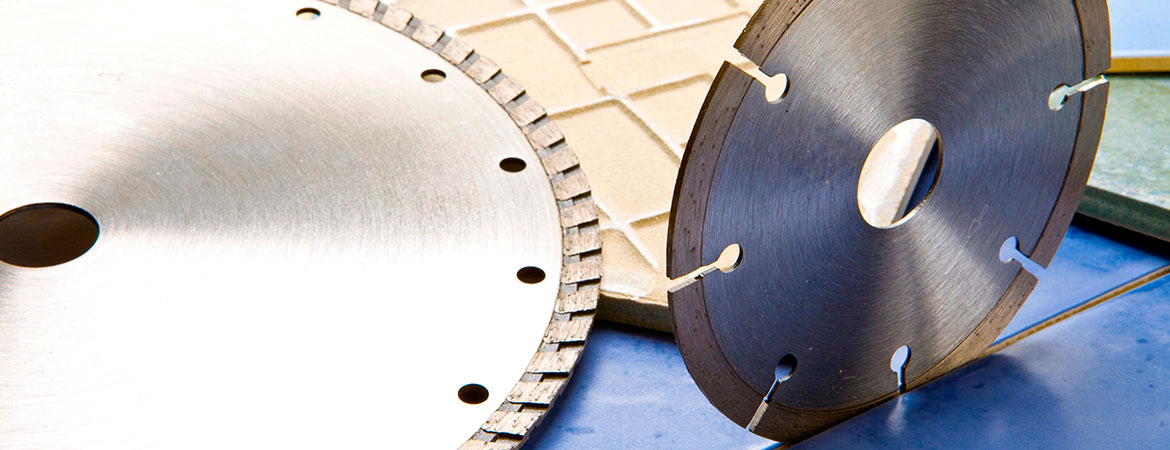

Diamond polishing pads are usually bought in sets with each pad featuring a different “grit” size, with lower numbered pads being used for the initial processes and then increasingly larger grit numbers to produce the final finish. Generally it is recommended that the user starts with a number 50 grit polishing pad, moving the grinder in circular movements for an even finish, using successively higher pad numbers as the job progresses.

Diamond polishing pads contain industrial diamonds suspended in either a resin or a ceramic bond, to form the grit. It is the grinding action of the diamond content which has the polishing effect on the surface of the stone and, as the bond wears away during polishing, fresh diamonds are exposed, maintaining the abrasive nature of the pad. Using successively finer grit sizes (higher pad numbers) throughout the job will gradually produce a polished finish.

It is important to remember to periodically remove any dust from the surface as it may contain diamonds from the pad which could then score or scratch the stone.

Once all the different grit sizes have been used a mirror shine should have been achieved. If this is insufficient, the stone can be given a final polish with the buffer pad if desired.

Do I Need Wet or Dry Diamond Polishing Pads?

Diamond polishing pads can be specifically for either wet or dry usage. Wet diamond polishing pads usually offer a longer lifespan, as they are able to withstand higher temperatures for longer due to the cooling effect of the water. However the presence of large volumes of water can make them impractical to use, for example if polishing a kitchen worktop which is already installed.

Dry diamond polishing pads are ideal for use in finished jobs where wet pads would not be practical, however it is important to be properly protected against dust inhalation.

For both types of diamond polishing pads it is important to ensure that you are using an appropriate grinder and, for the best finish, use each of the different grit sizes consecutively to produce high shine results.