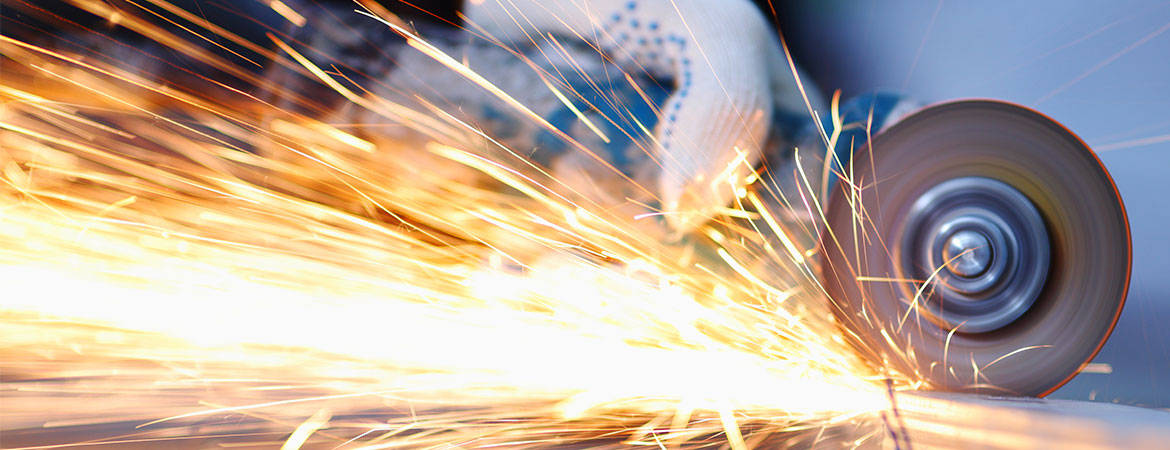

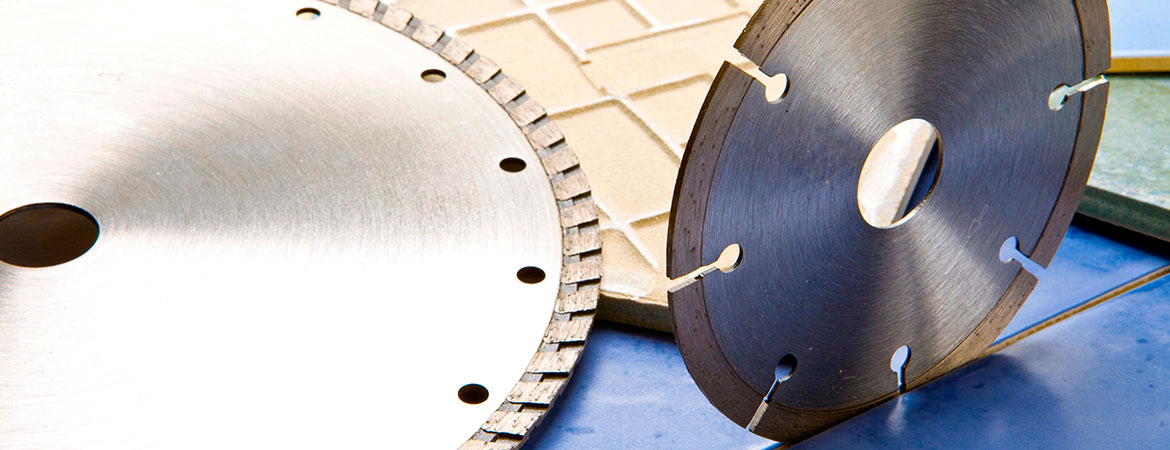

Cut-off saws (variously known as disc cutters, skill saws, Stihl saws, con saws or ‘whizzers’) are widely used in the construction industry. Diamond tip blades cut more quickly than abrasive wheels. Normally a blade with a diamond tip will cut a paving slab in about one minute. Using water significantly increases the life of the wheels/discs as well as prolonging the life of the motor by reducing the amount of dust that it works in. Even with the use of water suppression or extraction, suitable RPE with an assigned protection factor of at least 20 will still be needed, for example either FFP3 filtering face masks or respirators with P3 filters. Wearers should be appropriately trained and face fit tested for the equipment.

Cut-off Saws – Diamond Cutting Do’s

- Always refer to manufacturer’s operating manual for proper blade specifications, setup, as well as blade and machine maintenance.

- Inspect the blade often, checking for damage or fatigue – a damaged blade can be dangerous.

- Check mounting flanges for equal diameter, excessive wear or flatness.

- Mount the blade correctly and securely – a little more attention setting up can save your blade and also avoid accidents.

- Check the cut off saw to ensue its set up to operate properly:

- All fluids are at the recommended level.

- Spindle bearing should be free of end and radial play.

- V-belts should be properly tensioned and pulleys checked for excessive wear.

- Lead-off adjustment is set correctly, to allow the blades to travel straight.

- Blade guard is in place and properly secured.

6. Wear proper safety gear when operating saws and grinders, including: safety glasses and helmet, proper safety shoes and gloves, and hearing protection – don’t risk it! Wear the right safety gear, it’s no good being wise after the event.

7. Maintain a firm grip on hand-held saws during cutting operation.

8. For wet cutting, ensure continuous water flow to each side of the blade. An adequate coolant supply is required for wet cutting blades to maintain blade life and cutting efficiency.

Cut-off Saws – Diamond Cutting Don’ts

- Never operate a cutting saw, wet or dry, without proper safety guards in place!

- Don’t use a diamond blade without checking manufacturer’s recommendations for the material to be cut – you will get a cleaner cut, a quicker cut and avoid blade accidents.

- Don’t dry cut unless a blade is specifically designated to do so by the manufacturer.

- Don’t use a new or used diamond blade with a core that is not flat or is cracked.

- Don’t force the blade onto machine blade shaft, alter the size of the mounting hole, or tighten mounting nut excessively.

- Don’t use mounting flanges on which the bearing surfaces are not clean and flat.

- Don’t mount the cutting blade on machine that does not meet the minimum requirements set forth in the manufacturer’s manual.

- Don’t exceed the maximum operating speed specified for the blade.

- Don’t stand in direct line with diamond or abrasive blades during start-up or operation.

- Don’t cut or grind with the sides of a blade.

- Don’t force a cut, allow the blade to deflect, or attempt to cut curves.

- When dry cutting, don’t make long, continuous cuts. Allow the blade to cool by turning in the air every 10 to 15 seconds.

Consider the health and safety of the operator and of others when cut-off saws are used. Use suitable personal protective equipment (PPE), such as hard hats, eye protection and ear defenders. Make sure these items are worn correctly and are suitable for use together. To protect passers-by from the ejection of shards or fragments during the cutting process some form of segregation may be required, eg screening or other physical barriers attached to scaffolding or inside buildings.

Consider the health and safety of the operator and of others when cut-off saws are used. Use suitable personal protective equipment (PPE), such as hard hats, eye protection and ear defenders. Make sure these items are worn correctly and are suitable for use together. To protect passers-by from the ejection of shards or fragments during the cutting process some form of segregation may be required, eg screening or other physical barriers attached to scaffolding or inside buildings.

2 thoughts on “Cut-off Saws – the do’s and dont’s”

Comments are closed.